Manufacturing Methodology

Scope Boundary

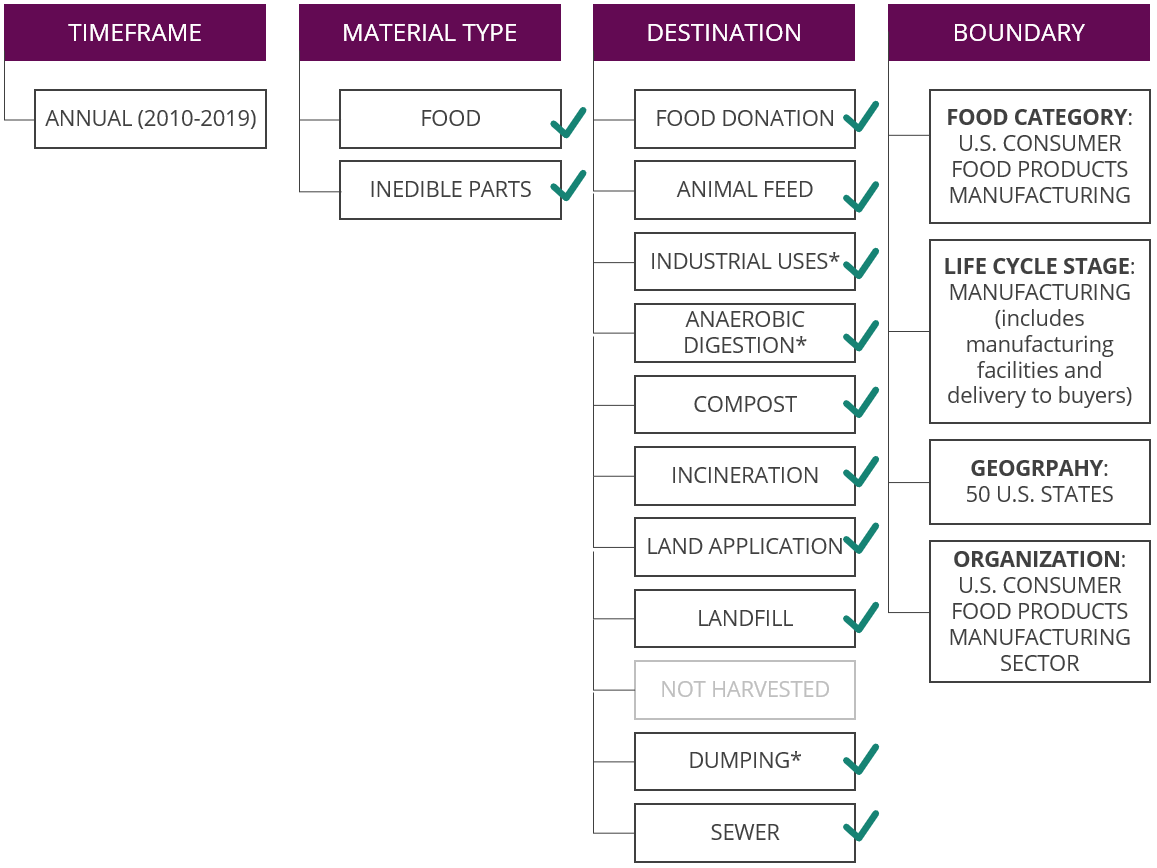

This diagram communicates the scope boundary as aligned with the Food Loss and Waste Accounting and Reporting Standard[17]. Note that ReFED’s analysis also includes food sent to donations, although donations are not considered a destination within the Standard.

- NOTES

“Food Donation” has been added as a Destination

“Biomaterial Processing is referred to as “Industrial Uses” in our model

“Co/anaerobic digestion” is referred to as “Anaerobic digestion” in our model

“Controlled Combustion” is referred to as “Incineration” in our model

“Refuse/discards” is referred to as “Dumping” in our model

Calculations

Surplus Food Calculations

In ReFED’s data model, the following calculations are repeated for every state, year, and manufacturing food type before any aggregation is done.

DATA ITEM |

DATA SOURCE OR CALCULATION |

EXAMPLE |

|

|---|---|---|---|

National US Dollars Wholesale Value Shipped |

U.S. Census Bureau Annual Survey of Manufactures[3] |

$4,757,890,000 wholesale value of Tortilla Manufacturing products shipped in 2020 from U.S. manufacturers |

|

Percent of Shipments Used in Food Products |

U.S. Census Bureau Annual Survey of Manufactures - Industry Product Analysis[3] |

97.27% of Tortilla Manufacturing shipments in 2020 were used in food products |

|

Retail Markup |

U.S. Census Bureau Annual Retail Trade Survey[4] |

The average gross margin for U.S. grocery retailers in 2020 was 27.40% (See Appendix H) |

|

National US Dollars Retail Value Shipped |

= National US Dollars Wholesale Value Shipped * ( 100% + Retail Markup ) |

= $4,757,890,000 wholesale value shipped * (100% + 27.40% margin)

= $5,895,768,416 retail value of manufacturing products shipped

|

|

Retail Price per Lb (National) |

U.S. Grocery Retail Dollar-to-Weight Conversion Factors Report[40] |

Average retail price $1.58 per lb for Tortilla Manufacturing products |

|

State Share of Employees |

= 8.08% of Tortilla Manufacturing employees in Illinois in 2020

|

||

US Dollars Retail Value Shipped |

= US Dollars National Retail Value Shipped * State Share of Employees |

= $5,895,768,416 retail value shipped from all U.S. manufacturers * 8.08% of employees located in Illinois

= $476,613,918 estimated retail value of Tortilla Manufacturing products shipped from Illinois in 2020

|

|

Tons Shipped |

= US Dollars Retail Value Shipped / Retail Price per Lb / 2,000 lbs per ton |

= $476,613,918 retail value shipped / $1.58 per lb

= 151,072 estimated tons of Tortilla Manufacturing products shipped from Illinois in 2020

|

|

FINISHED PRODUCT NOT SHIPPED |

|||

% of Finished Product Shipped |

Tesco Supplier Case Studies[45] (See Appendix I) |

In the General Mills Tesco Supplier Case study (used as a proxy as no Tortilla Manufacturing-specific study was available), 0.26% of manufactured products are finished into a final product but never shipped. |

|

Tons Finished Product Manufactured |

= Tons Shipped / ( 100% - % of Finished Product Unshipped ) |

= 151,072 tons shipped / ( 100% - 0.26% unshipped finished product )

= 151,466 tons of Tortilla Manufacturing products manufactured in Illinois

|

|

Tons Finished Product Not Shipped |

= Tons Finished Product Manufactured - Tons Finished Product Shipped |

= 151,466 tons manufactured - 151,072 tons shipped

= 393 tons of Tortilla Manufacturing products not shipped in Illinois

|

|

Finished Product Price per Lb |

= Retail Price per Lb / Retail Markup |

= $1.58 retail price per lb / 27.40% grocery retailer markup

= $1.58 per lb of finished product

|

|

US Dollars Finished Product Not Shipped |

= Tons Finished Product Not Shipped * Finished Product Price per Lb / 2,000 lbs per ton |

= 393 tons not shipped * $1.58 per lb / 2,000 lbs per ton

= $1,241,653 of Tortilla Manufacturing products not shipped in Illinois

|

|

BUYER REJECTIONS |

|||

Buyer Rejection Rate |

Expert Interviews |

According to expert interviews, about 0.50% of Breads & Bakery shipments are rejected by buyers |

|

% of Buyer Rejections Sold via Discount Outlets |

Expert interviews |

Based on expert interviews, ReFED assumed that 25.00% of product rejected by buyer quality assurance teams ends up being sold via other channels and does not get wasted. |

|

Tons Unsold Buyer Rejections |

= Tons Shipped * Buyer Rejection Rate * ( 100% - % of Buyer Rejections Sold via Discount Outlets ) |

= 151,072 tons shipped * 0.50% rejected by buyers * ( 100% - 25.00% of rejections sold via discount outlets)

= 566 tons unsold buyer rejections

|

|

US Dollars Unsold Buyer Rejections |

= US Dollars Retail Value Shipped - * ( 100% - % of Buyer Rejections Sold via Discount Outlets ) |

= $476,613,918 shipped * 0.50% rejected by buyers * ( 100% - 25.00% of rejections sold via discount outlets)

= $1,787,302 unsold buyer rejections

|

|

UNUTILIZED INGREDIENTS |

|||

Recipe Tons Ingredient per Ton Finished Product |

Multiple Data Sources[2],[7],[9],[10],[16],[19],[20],[21],[18],[23],[24],[27],[28],[31],[33],[36],[37],[22],[58] |

__manufacturing_example_ingredients_herbs_spices_and_seasonings_tons_ingredient_category_per_ton_product__ tons Herbs, Spices, And Seasonings per ton finished Tortilla Manufacturing products

__manufacturing_example_ingredients_flour_and_meal_tons_ingredient_category_per_ton_product__ tons Flour And Meal per ton finished Tortilla Manufacturing products

__manufacturing_example_ingredients_shortening_and_lard_tons_ingredient_category_per_ton_product__ tons Shortening And Lard per ton finished Tortilla Manufacturing products

__manufacturing_example_ingredients_baking_milks_tons_ingredient_category_per_ton_product__ tons Baking Milks per ton finished Tortilla Manufacturing products

__manufacturing_example_ingredients_baking_yeast_tons_ingredient_category_per_ton_product__ tons Baking Yeast per ton finished Tortilla Manufacturing products

|

|

Tons of each Ingredient Utilized in Finished Product |

= Tons Production * Tons of each Ingredient per Ton of Finished Product |

Water and additives are not considered “food” in this methodology.

Herbs, Spices, And Seasonings :

= 151,466 tons of Tortilla Manufacturing products produced * __manufacturing_example_ingredients_herbs_spices_and_seasonings_tons_ingredient_category_per_ton_product__ tons Herbs, Spices, And Seasonings per ton finished product

= 4,543 tons Herbs, Spices, And Seasonings utilized

Flour And Meal :

= 151,466 tons of Tortilla Manufacturing products produced * __manufacturing_example_ingredients_flour_and_meal_tons_ingredient_category_per_ton_product__ tons Flour And Meal per ton finished product

= 31,807 tons Flour And Meal utilized

Shortening And Lard:

= 151,466 tons of Tortilla Manufacturing products produced * __manufacturing_example_ingredients_shortening_and_lard_tons_ingredient_category_per_ton_product__ tons Shortening And Lard per ton finished product

= 15,146 tons __manufacturing_example_ingredients_shortening_and_lard_tons_ingredient_category_per_ton_product__ tons Shortening And Lard utilized

Baking Milks :

= 151,466 tons of Tortilla Manufacturing products produced * __manufacturing_example_ingredients_baking_milks_tons_ingredient_category_per_ton_product__ tons Baking Milks per ton finished product

= 3,029 tons Baking Milks utilized

Baking Yeast :

= 151,466 tons of Tortilla Manufacturing products produced * __manufacturing_example_ingredients_baking_yeast_tons_ingredient_category_per_ton_product__ tons Baking Yeast per ton finished product

= 1,514 tons Baking Yeast utilized

|

|

Ingredient Utilization Rates |

Tesco Supplier Case Studies[45] |

Tesco Supplier Case Studies provided ingredient utilization rates for many different types of food manufacturers. General Mills, for example, had a utilization rate of 95.43%, and this was used to approximate ingredient utilization for Tortilla Manufacturing products. |

|

Tons Ingredients Purchased |

= Tons Utilized Ingredients / Ingredient Utilization Rate |

Herbs, Spices, And Seasonings:

= 4,543 utilized / 95.43% utilization rate

= 4,761 tons Herbs, Spices, And Seasonings purchased

Flour And Meal:

= 31,807 tons Flour And Meal utilized / 95.43% utilization rate

= 33,332 tons Flour And Meal purchased

Shortening And Lard:

= 15,146 tons Shortening And Lard utilized / 95.43% utilization rate

= 15,872 tons Shortening And Lard purchased

Baking Milks:

= 3,029 tons Baking Milks utilized / 95.43% utilization rate

= 3,174 tons Baking Milks purchased

Baking Yeast:

= 1,514 tons Baking Yeast utilized / 95.43% utilization rate

= 1,587 tons Baking Yeast purchased

|

|

Wholesale Price per Ton for each Ingredient |

= Retail Price per Lb (National) * ( 100% - Grocery Retail Markup ) * 2,000 lbs per ton |

Herbs, Spices, And Seasonings:

= $4.73 per lb average grocery retail price * ( 100% - 27.40% grocery markup ) * 2,000 lbs per ton

= $6,870 wholesale price per ton

Flour And Meal:

= $0.71 per lb average grocery retail price * ( 100% - 27.40% grocery markup ) * 2,000 lbs per ton

= $1,035 wholesale price per ton

Shortening And Lard:

= $1.74 per lb average grocery retail price * ( 100% - 27.40% grocery markup ) * 2,000 lbs per ton

= $2,531 wholesale price per ton

Baking Milks:

= $1.95 per lb average grocery retail price * ( 100% - 27.40% grocery markup ) * 2,000 lbs per ton

= $2,824 wholesale price per ton

Baking Yeast:

= $19.13 per lb average grocery retail price * ( 100% - 27.40% grocery markup ) * 2,000 lbs per ton

= $27,780 wholesale price per ton

|

|

US Dollars Ingredients Purchased |

= Tons Ingredients Purchased * Wholesale Price per Ton |

Herbs, Spices, And Seasonings:

= 4,761 tons Herbs, Spices, And Seasonings purchased * $6,870 per ton

= $32,713,471 Herbs, Spices, And Seasonings purchased

Flour And Meal:

= 33,332 tons Flour And Meal purchased * $1,035 per ton

= $34,505,748 Flour And Meal purchased

Shortening And Lard:

= 15,872 tons Shortening And Lard s purchased * $2,531 per ton

= $40,182,689 Shortening And Lard purchased

Baking Milks:

= 3,174 tons Baking Milks purchased * $2,824 per ton

= $8,965,321 Baking Milks purchased

Baking Yeast:

= 1,587 tons Baking Yeast purchased * $27,780 per ton

= $44,094,423 Baking Yeast purchased

|

|

Tons of Ingredients Unutilized |

= Tons of Ingredient Purchased - Tons of Ingredients Utilized |

Herbs, Spices, And Seasonings:

= 4,761 tons purchased - 4,543 tons utilized

= 217 tons unutilized

Flour And Meal:

= 33,332 tons purchased - 31,807 tons utilized

= 1,524 tons unutilized

Shortening And Lard:

= 15,872 tons purchased - 15,146 tons utilized

= 725 tons unutilized

Baking Milks:

= 3,174 tons purchased - 3,029 tons utilized

= 145 tons unutilized

Baking Yeast:

= 1,587 tons purchased - 1,514 tons utilized

= 72 tons unutilized

Total Tons Unutilized Ingredients:

= 217 tons Herbs, Spices, And Seasonings unutilized + 1,524 tons Flour And Meal unutilized + 725 tons Shortening And Lard unutilized + 145 tons Baking Milks unutilized + 72 tons Baking Yeast unutilized

= 2,685 total tons unutilized ingredients

|

|

US Dollars Unutilized Ingredients |

= Tons of Ingredient Unutilized * Wholesale price per ton |

Herbs, Spices, And Seasonings:

= 217 tons unutilized * $6,870 per ton

= $1,496,023 unutilized

Flour And Meal:

= 1,524 tons unutilized * $1,035 per ton

= $1,577,986 unutilized

Shortening And Lard:

= 725 tons unutilized * $2,531 per ton

= $1,837,599 unutilized

Baking Milks:

= 145 tons unutilized * $2,824 per ton

= $409,994 unutilized

Baking Yeast:

= 72 tons unutilized * $27,780 per ton

= $2,016,487 unutilized

Total US Dollars Unutilized Ingredients:

= $1,496,023 Herbs, Spices, And Seasonings unutilized + $1,577,986 Flour And Meal unutilized + $1,837,599 Shortening And Lard unutilized + $409,994 Baking Milks unutilized + $2,016,487 Baking Yeast unutilized

= $7,338,092 unutilized ingredients

|

|

TOTALS |

|||

Tons Unsold Food |

= Tons Unutilized Ingredients + Tons Unshipped Product + Tons Unsold Buyer Rejections |

= 2,685 tons unutilized ingredients + 393 tons finished product not shipped + 566 tons unsold buyer rejections

= 3,645 tons unsold food in the Tortilla Manufacturing industry in Illinois in 2020

|

|

US Dollars Unsold Food |

= US Dollars Unutilized Ingredients + US Dollars Unshipped Product + US Dollars Unsold Buyer Rejections |

= $7,338,092 unutilized ingredients + $1,241,653 finished product not shipped + $1,787,302 buyer rejections

= $10,367,048 unsold food in the Tortilla Manufacturing industry in Illinois in 2020

|

|

Tons Supply |

= Sum of Ingredient Tons Purchased |

= 4,761 tons Herbs, Spices, And Seasonings purchased + 33,332 tons Flour And Meal purchased + 15,872 tons Shortening And Lard purchased + 3,174 tons Baking Milks purchased + 1,587 tons Baking Yeast purchased

= 58,728 tons Tortilla Manufacturing ingredients purchased in Illinois in 2020

|

|

US Dollars Supply |

= Sum of Ingredient US Dollars Purchased |

= $32,713,471 Herbs, Spices, And Seasonings purchased + $34,505,748 Flour And Meal purchased + $40,182,689 Shortening And Lard purchased + $8,965,321 Baking Milks purchased + $44,094,423 Baking Yeast purchased

= $160,461,655 Tortilla Manufacturing ingredients purchased in Illinois in 2020

|

|

Cause Calculations

DATA ITEM |

DATA SOURCE OR CALCULATION |

EXAMPLE |

|

|---|---|---|---|

UNUTILIZED INGREDIENTS |

|||

% Unutilized due to Cause |

Tesco Supplier Case Studies[45] |

ReFED assumed that 100% of unutilized ingredients were Byproducts & Production Line Waste after reviewing the supplier case studies. |

|

Tons Unutilized Ingredients due to Cause |

= Tons Unutilized Ingredients * % Unutilized due to Cause |

Tons unutilized due to Byproducts & Production Line Waste:

= 2,685 tons unutilized ingredients * 100% unutilized due to Byproducts & Production Line Waste

= 2,685 tons

|

|

US Dollars Unutilized Ingredients due to Cause |

= US Dollars Unutilized Ingredients * % Unutilized due to Cause |

US Dollars of ingredients unutilized due to Byproducts & Production Line Waste:

= $7,338,092 unutilized ingredients * 100% unutilized due to Byproducts & Production Line Waste

= $7,338,092

|

|

UNSHIPPED PRODUCT |

|||

% Unshipped due to Cause |

ReFED was unable to find any data sources that quantify the breakdown of the causes of unshipped product (e.g., misprints versus discontinued product), so this cause was not broken down any further. |

100% due to ‘Unshipped Finished Product’ |

|

Tons Unshipped Product due to Cause |

= Tons Unshipped Product * % due to ‘Unshipped Finished Product’ |

= 393 tons unshipped Tortilla Manufacturing products * 100%

= 393 tons unshipped product

|

|

US Dollars Unshipped Product |

= US Dollars Unshipped Product * % due to ‘Unshipped Finished Product’ |

= $1,241,653 unshipped Tortilla Manufacturing products * 100%

= $1,241,653 unshipped product

|

|

BUYER REJECTIONS |

|||

Tons Unsold Buyer Rejections |

See calculation above for Tons Buyer Rejections |

= 566 tons unsold buyer rejections |

|

US Dollars Unsold Buyer Rejections |

See calculation above for US Dollars Unsold Buyer Rejections |

= $1,787,302 unsold buyer rejections |

|

Destination Calculations

DATA ITEM |

DATA SOURCE OR CALCULATION |

EXAMPLE |

|

|---|---|---|---|

Destination Breakdown of Unutilized Ingredients (See Appendix J) |

Northstar Recycling |

This was the destinations breakdown for Bakery manufacturers based on aggregated data from NorthStar Recycling:

donations: __manufacturing_example_ingredients_percent_donations__%

Animal feed: 98.51%

————————————————

Total: 100%

|

|

Destination Breakdown of Unshipped Finished Product (See Appendix J) |

Northstar Recycling |

This was the destinations breakdown for Bakery manufacturers based on aggregated data from NorthStar Recycling:

donations: __manufacturing_example_finished_product_percent_donations_unshipped_product__%

Animal feed: 98.51%

————————————————

Total: 100%

|

|

Destination Breakdown of Buyer Rejections |

Expert Interviews |

ReFED estimated the following breakdown of unsold buyer rejections based on expert interviews:

Donations: __manufacturing_example_finished_product_percent_donations_unsold_buyer_rejections__%

Animal feed: 33.33%

Trash: 33.33%

————————————————

Total: 100%

|

|

% of Trash that is landfill vs incineration in Illinois (Biocycle/Columbia University Survey[8]) (See Appendix Z) |

% of Trash that is landfill = 100.00%

% of Trash that is incineration = 0.00%

|

||

Breaking “Trash” into Landfill vs Incineration: |

|||

% landfill = % Trash * % of Trash that is landfill |

% landfill:

|

= 33.33% * 100.00%

= __manufacturing_example_unsold_buyer_rejections_percent_landfill__%

|

|

% incineration = % Trash * % of Trash that is incineration |

% incineration:

|

= 33.33% * 0.00%

= __manufacturing_example_unsold_buyer_rejections_percent_incineration__%

|

|

Tons donations |

= Tons Unutilized Ingredients * % Donations_UI + Tons Unshipped Product * % Donations_UP + Tons Unsold Buyer Rejections * % Donations_BR

Note:

_UI means Unutilized Ingredients

_UP means Unshipped Finished Product

_BR means Buyer Rejections

|

= 2,685 tons unutilized ingredients * __manufacturing_example_ingredients_percent_donations__% + 393 tons unshipped Tortilla Manufacturing products * __manufacturing_example_finished_product_percent_donations_unshipped_product__% + 566 tons unsold buyer rejections * __manufacturing_example_finished_product_percent_donations_unsold_buyer_rejections__%

= __manufacturing_example_total_tons_donations__ tons donations

|

|

Tons Animal Feed |

= Tons Unutilized Ingredients * % Animal Feed_UI + Tons Unshipped Product * % Animal Feed_UP + Tons Unsold Buyer Rejections * % Animal Feed_BR |

= 2,685 tons unutilized ingredients * 98.51% + 393 tons unshipped Tortilla Manufacturing products * 98.51% + 566 tons unsold buyer rejections * 33.33%

= 3,222 tons sent to animal feed

|

|

Tons Anaerobic Digestion |

= Tons Unutilized Ingredients * % Anaerobic Digestion_UI + Tons Unshipped Product * % Anaerobic Digestion_UP + Tons Unsold Buyer Rejections * % Anaerobic Digestion_BR |

= 2,685 tons unutilized ingredients * 0% + 393 tons unshipped Tortilla Manufacturing products * __manufacturing_example_finished_product_percent_anaerobic_digestion_unshipped_product__% + 566 tons unsold buyer rejections * __manufacturing_example_finished_product_percent_anaerobic_digestion_unsold_buyer_rejections__%

= __manufacturing_example_total_tons_anaerobic_digestion__ tons sent to anaerobic digestion

|

|

Tons composting |

= Tons Unutilized Ingredients * % composting_UI + Tons Unshipped Product * % composting_UP + Tons Buyer Rejections * % composting_BR |

= 2,685 tons unutilized ingredients * 0% + 393 tons unshipped Tortilla Manufacturing products * __manufacturing_example_finished_product_percent_composting_unshipped_product__% + 566 tons unsold buyer rejections * __manufacturing_example_finished_product_percent_composting_unsold_buyer_rejections__%

= __manufacturing_example_total_tons_composting__ tons sent to composting

|

|

Tons Industrial uses |

= Tons Unutilized Ingredients * % Industrial uses_UI + Tons Unshipped Product * % Industrial uses_UP + Tons Unsold Buyer Rejections * % Industrial uses_BR |

= 2,685 tons unutilized ingredients * 0% + 393 tons unshipped Tortilla Manufacturing products * __manufacturing_example_finished_product_percent_industrial_uses_unshipped_product__% + 566 tons unsold buyer rejections * __manufacturing_example_finished_product_percent_industrial_uses_unsold_buyer_rejections__%

= __manufacturing_example_total_tons_industrial_uses__ tons sent to industrial uses

|

|

Tons Land Application |

= Tons Unutilized Ingredients * % Land Application_UI + Tons Unshipped Product * % Land Application_UP + Tons Unsold Buyer Rejections * % Land Application_BR |

= 2,685 tons unutilized ingredients * 0% + 393 tons unshipped Tortilla Manufacturing products * 0.00% + 566 tons unsold buyer rejections * 0.00%

= 0 tons sent to land application

|

|

Tons Sewer |

= Tons Unutilized Ingredients * % Sewer_UI + Tons Unshipped Product * % Sewer_UP + Tons Unsold Buyer Rejections * % Sewer_BR |

= 2,685 tons unutilized ingredients * 0% + 393 tons unshipped Tortilla Manufacturing products * 0.00% + 566 tons unsold buyer rejections * 0.00%

= 0 tons sent to sewer

|

|

Tons Dumping |

= Tons Unutilized Ingredients * % Dumping_UI + Tons Unshipped Product * % Dumping_UP + Tons Unsold Buyer Rejections * % Dumping_BR |

= 2,685 tons unutilized ingredients * 0% + 393 tons unshipped Tortilla Manufacturing products * __manufacturing_example_finished_product_percent_dumping_unshipped_product__% + 566 tons unsold buyer rejections * __manufacturing_example_finished_product_percent_dumping_unsold_buyer_rejections__%

= __manufacturing_example_total_tons_dumping__ tons dumped

|

|

Tons landfill |

= Tons Unutilized Ingredients * % landfill_UI + Tons Unshipped Product * % landfill_UP + Tons Unsold Buyer Rejections * % landfill_BR |

= 2,685 tons unutilized ingredients * 0% + 393 tons unshipped Tortilla Manufacturing products * 0% + 566 tons buyer rejections * __manufacturing_example_unsold_buyer_rejections_percent_landfill__%

= __manufacturing_example_total_tons_landfill__ tons sent to landfill

|

|

Tons incineration |

= Tons Unutilized Ingredients * % incineration_UI + Tons Unshipped Product * % incineration_UP + Tons Buyer Rejections * % incineration_BR |

= 2,685 tons unutilized ingredients * 0% + 393 tons unshipped Tortilla Manufacturing products * 0% + 566 tons unsold buyer rejections * __manufacturing_example_unsold_buyer_rejections_percent_incineration__%

= __manufacturing_example_total_tons_incineration__ tons sent to incineration

|

|

US Dollars donations |

= US Dollars Unutilized Ingredients * % Donations_UI + US Dollars Unshipped Product * % Donations_UP + US Dollars Unsold Buyer Rejections * % Donations_BR |

= $7,338,092 unutilized ingredients * __manufacturing_example_ingredients_percent_donations__% + $1,241,653 unshipped Tortilla Manufacturing products * __manufacturing_example_finished_product_percent_donations_unshipped_product__% + $1,787,302 unsold buyer rejections * __manufacturing_example_finished_product_percent_donations_unsold_buyer_rejections__%

= $__manufacturing_example_total_us_dollars_donations__ Tortilla Manufacturing products donations

|

|

US Dollars Animal Feed |

= US Dollars Unutilized Ingredients * % Animal Feed_UI + US Dollars Unshipped Product * % Animal Feed_UP + US Dollars Unsold Buyer Rejections * % Animal Feed_BR |

= $7,338,092 unutilized ingredients * 98.51% + $1,241,653 unshipped Tortilla Manufacturing products * 98.51% + $1,787,302 unsold buyer rejections * 33.33%

= $9,047,658 sent to animal feed

|

|

US Dollars Anaerobic Digestion |

= US Dollars Unutilized Ingredients * % Anaerobic Digestion_UI + US Dollars Unshipped Product * % Anaerobic Digestion_UP + US Dollars Unsold Buyer Rejections * % Anaerobic Digestion_BR |

= $7,338,092 unutilized ingredients * 0% + $1,241,653 unshipped Tortilla Manufacturing products * __manufacturing_example_finished_product_percent_anaerobic_digestion_unshipped_product__% + $1,787,302 unsold buyer rejections * __manufacturing_example_finished_product_percent_anaerobic_digestion_unsold_buyer_rejections__%

= $__manufacturing_example_total_us_dollars_anaerobic_digestion__ sent to anaerobic digestion

|

|

US Dollars composting |

= US Dollars Unutilized Ingredients * % composting_UI + US Dollars Unshipped Product * % compostingUP + US Dollars Buyer Rejections * % composting_BR |

= $7,338,092 unutilized ingredients * 0% + $1,241,653 unshipped Tortilla Manufacturing products * __manufacturing_example_finished_product_percent_composting_unshipped_product__% + $1,787,302 unsold buyer rejections * __manufacturing_example_finished_product_percent_composting_unsold_buyer_rejections__%

= $__manufacturing_example_total_us_dollars_composting__ sent to composting

|

|

US Dollars Industrial uses |

= US Dollars Unutilized Ingredients * % Industrial uses_UI + US Dollars Unshipped Product * % Industrial uses_UP + US Dollars Unsold Buyer Rejections * % Industrial uses_BR |

= $7,338,092 unutilized ingredients * 0% + $1,241,653 unshipped Tortilla Manufacturing products * __manufacturing_example_finished_product_percent_industrial_uses_unshipped_product__% + $1,787,302 unsold buyer rejections * __manufacturing_example_finished_product_percent_industrial_uses_unsold_buyer_rejections__%

= $__manufacturing_example_total_us_dollars_industrial_uses__ sent to industrial uses

|

|

US Dollars Land Application |

= US Dollars Unutilized Ingredients * % Land Application_UI + US Dollars Unshipped Product * % Land Application_UP + US Dollars Buyer Rejections * % Land Application_BR |

= $7,338,092 unutilized ingredients * 0% + $1,241,653 unshipped Tortilla Manufacturing products * 0.00% + $1,787,302 unsold buyer rejections * 0.00%

= $0 sent to land application

|

|

US Dollars Sewer |

= US Dollars Unutilized Ingredients * % Sewer_UI + US Dollars Unshipped Product * % Sewer_UP + US Dollars Unsold Buyer Rejections * % Sewer_BR |

= $7,338,092 unutilized ingredients * 0% + $1,241,653 unshipped Tortilla Manufacturing products * 0.00% + $1,787,302 unsold buyer rejections * 0.00%

= $0 sent to sewer

|

|

US Dollars Dumping |

= US Dollars Unutilized Ingredients * % Dumping_UI + US Dollars Unshipped Product * % Dumping_UP + US Dollars Unsold Buyer Rejections * % Dumping_BR |

= $7,338,092 unutilized ingredients * 0% + $1,241,653 unshipped Tortilla Manufacturing products * __manufacturing_example_finished_product_percent_dumping_unshipped_product__% + $1,787,302 unsold buyer rejections * __manufacturing_example_finished_product_percent_dumping_unsold_buyer_rejections__%

= $__manufacturing_example_total_us_dollars_dumping__ dumped

|

|

US Dollars landfill |

= US Dollars Unutilized Ingredients * % landfill_UI + US Dollars Unshipped Product * % landfill_UP + US Dollars Unsold Buyer Rejections * % landfill_BR |

= $7,338,092 unutilized ingredients * 0% + $1,241,653 unshipped Tortilla Manufacturing products * 0% + $1,787,302 unsold buyer rejections * __manufacturing_example_unsold_buyer_rejections_percent_landfill__%

= $__manufacturing_example_total_us_dollars_landfill__ sent to landfill

|

|

US Dollars incineration |

= US Dollars Unutilized Ingredients * % incineration_UI + US Dollars Unshipped Product * % incineration_UP + US Dollars Unsold Buyer Rejections * % incineration_BR |

= $7,338,092 unutilized ingredients * 0% + $1,241,653 unshipped Tortilla Manufacturing products * 0% + $1,787,302 unsold buyer rejections * __manufacturing_example_unsold_buyer_rejections_percent_incineration__%

= $__manufacturing_example_total_us_dollars_incineration__ sent to incineration

|

|

Data Sources and Limitations

National Value Shipped

Retail Markup

Retail Price per Lb

Nielsen data represents over 85% coverage of grocery retail sales in the U.S. Each year top U.S. grocery retailers report item level point-of-sale sales data to Nielsen, including information about each item such as the grocery chain where it was sold, the brand name of the product, the food classification (department, category, subcategory), the weight of food and packaging, and many other attributes. ReFED used this data to quantify the retail value and weight of food sold by grocery retailers in the U.S. by year, state, and food type. For more information about the weight data, see U.S. Grocery Retail Dollar-to-Weight Conversion Factors Report[40].

The accuracy of these estimates is limited to the accuracy of the Nielsen sales and weight data. The weight data for UPC items comes directly from up-to-date product packaging images. For non-UPC items sold in eaches, Nielsen estimates weight using a weight conversion factor (e.g., the average weight of a lemon). For other non-UPC items, Nielsen is reliant on the retailer transaction data to provide the item sale weight units (e.g., lbs of apples sold).

Employees

Each year the U.S. Census Bureau releases the number of employees working in various industry types in addition to many other data points[46]. Every business is categorized into an industry code according to the North America Industry Classification System (NAICS). ReFED used the number of employees working in each food manufacturing industry type (e.g., __food_var__ manufacturing) in each state on an annual basis to allocate national food manufacturing shipments to individual states.

Unshipped Product Rates

Buyer Rejection Rates

Recipes

Ingredient Utilization Rates

Wholesale Ingredient Prices

Unutilized Ingredient Destinations

ReFED used custom-prepared food waste destinations data from Northstar Recycling[59] to estimate the destination breakdown of unutilized food manufacturing ingredients by food manufacturing type (See Appendix J). Northstar Recycling is a national waste and recycling company that manages waste for many food manufacturers across the U.S. and Canada. Because Northstar does not manage food waste for any meat processing facilities, ReFED assumed that 100% of unutilized ingredients at meat processing plants were sent to rendering (industrial uses). Additionally, Northstar does not have visibility to food donations data for their clients, so ReFED assumed that 1% of unutilized ingredients are donations based on data from the 2016 Food Waste Reduction Alliance survey[14] in which 9 manufacturers responded (6.2% of U.S. market share based on sales). Because these data sources are based on a single year, the data does not provide insight into changes in disposal habits over time.

Unshipped Product Destinations

Retail Rejection Destinations

Based on expert interviews, ReFED assumed the following destinations breakdown for product that gets rejected by buyers: 25% sold to discount outlets, 25% trash, 25% donations, and 25% animal feed. The portion sold to discount outlets was subtracted from the surplus total. Better data is needed in this area to replace these anecdotal estimates.

Data Quality Evaluation

This rubric is designed to evaluate the quality of how each data source was utilized by ReFED to estimate food loss and waste. It is not meant to rate the quality of the study itself. See Appendix AA for more information about the ReFED Data Quality Rubric.

Table 8. Data Quality Evaluation for Food Waste Monitor Manufacturing Sector

DATA |

SOURCE |

DATA QUALITY SCORE |

||||||

|---|---|---|---|---|---|---|---|---|

CREDIBILITY |

UPDATE FREQUENCY |

COVERAGE |

FOOD TYPE |

GEOGRAPHY |

SCORE |

WEIGHT |

||

MANUFACTURING SURPLUS DATA |

||||||||

National US Dollars Wholesale Value Shipped |

U.S. Census Bureau Annual Survey of Manufactures |

5 |

5 |

5 |

5 |

3 |

High 23/5 = 4.6 |

15% |

Retail Markup |

U.S. Census Bureau Annual Retail Trade Survey |

5 |

5 |

5 |

1 |

3 |

Medium 19/5 = 3.8 |

15% |

Retail Price per Lb |

U.S. Grocery Retail Dollar-to-Weight Conversion Factors Report |

4 |

5 |

5 |

5 |

3 |

High 22/5 = 4.4 |

15% |

Employees |

U.S. Bureau of Labor Statistics Employee Levels |

5 |

5 |

5 |

5 |

5 |

Very High 25/5 = 5.0 |

15% |

Buyer Rejection Rates |

Expert Interviews |

1 |

1 |

1 |

3 |

3 |

Very Low 9/5 = 1.8 |

5% |

Unshipped Product Rates |

Tesco Supplier Case Studies |

3 |

1 |

1 |

3 |

1 |

Very Low 9/5 = 1.8 |

5% |

Recipes |

Multiple Data Sources |

1 |

1 |

1 |

5 |

1 |

Very Low 9/5 = 1.8 |

10% |

Ingredient Utilization Rates |

Tesco Supplier Case Studies |

3 |

1 |

1 |

3 |

1 |

Very Low 9/5 = 1.8 |

20% |

4.6 * 15% + 3.8 * 15% + 4.4 * 15% + 5.0 * 15% + 1.8 * 5% + 1.8 * 5% + 1.8 * 10% + 1.8 * 20% = 3.39 |

Medium |

|||||||

MANUFACTURING CAUSES DATA |

||||||||

Ingredient Utilization Rates |

Tesco Supplier Case Studies |

3 |

1 |

1 |

3 |

1 |

Very Low 9/5 = 1.8 |

80% |

Unshipped Product Rates |

Tesco Supplier Case Studies |

3 |

1 |

1 |

3 |

1 |

Very Low 9/5 = 1.8 |

10% |

Buyer Rejection Rates |

Expert Interviews |

1 |

1 |

1 |

3 |

3 |

Very Low 9/5 = 1.8 |

10% |

1.8 * 80% + 1.8 * 10% + 1.8 * 10% = 1.8 |

Very Low |

|||||||

MANUFACTURING DESTINATIONS DATA |

||||||||

% Destination Breakdown of Unutilized Ingredients |

Northstar Recycling |

4 |

1 |

2 |

1 |

3 |

Low 11/5 = 2.2 |

78% |

% Destination Breakdown of Unshipped Finished Product |

Northstar Recycling |

1 |

1 |

1 |

3 |

3 |

Very Low 9/5 = 1.8 |

8% |

% Destination Breakdown of Buyer Rejections |

Expert Interviews |

1 |

1 |

1 |

1 |

3 |

Very Low 7/5 = 1.4 |

8% |

% of Trash landfill vs incineration |

Biocycle/Columbia University Survey |

5 |

2 |

4 |

1 |

5 |

Medium 17/5 = 3.4 |

6% |

2.2 * 78% + 1.8 * 8% + 1.4 * 8% + 3.4 * 6% = 2.18 |

Low |

|||||||